Pharmaceutical packaging requires accuracy, cleanliness, speed, and consistent product handling. Whether it’s transferring pill bottles, blister packs, or other packaged goods, every step must protect the product.

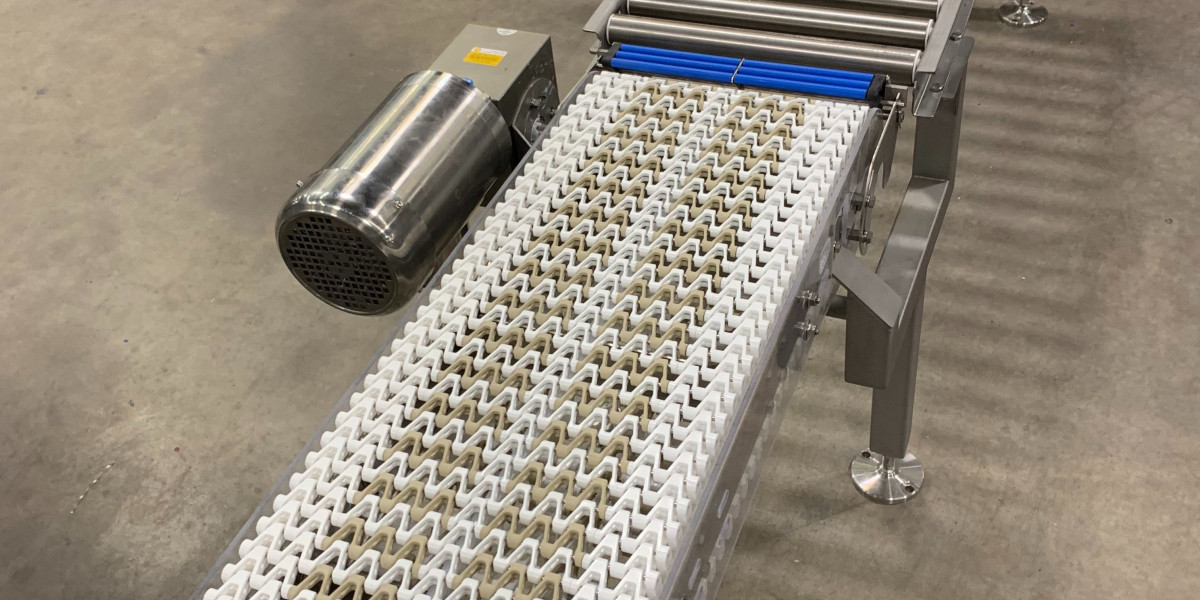

A transfer conveyor plays a key role in this, especially when working with fragile or uniform items. One small shift or misalignment can disrupt production or cause a batch to be rejected. That’s why many pharmaceutical lines rely on side belt transfer conveyors to guide items safely and precisely between stages.

Why Precision Matters in Medicine and Pill Bottle Transfers

When working with tablets, liquids, or capsules, maintaining the filling position is essential. Any tipping or misalignment during transfer can lead to spills, compromised product integrity, or disruptions in labelling. Precise spacing and controlled movement also support consistent performance of downstream systems.

A properly set up transfer conveyor can gently guide bottles or containers between stages without unwanted movement. With firm side support, bottles move without tipping, even across small gaps or during transitions.

The Key Transfer Conveyor Parts That Keep Products Safe

Pharmaceutical applications rely on well-designed parts that support sanitary handling and reduce contact. When these parts are chosen and installed carefully, they help protect product quality throughout the packaging process.

Some of the most important transfer conveyor parts include:

● Adjustable side belts that gently grip and stabilize each item.

● Smooth, easy-to-clean surfaces.

● Minimal contact points to reduce contamination risk.

● Guided transfer sections to control bottle or blister pack movement.

How Side Belt Transfer Conveyors Prevent Misalignment in Blister Pack Lines

Blister packs are often light and flexible, which makes them prone to slipping or skewing on flat belts. A side belt transfer conveyor holds the product from both sides, keeping each unit centred and steady.

This method helps reduce misfeeds, crooked seals, and sealing gaps. Keeping the pack secure as it moves from one section to another allows scanners and labellers to do their jobs properly.

Why Conveyor Speed Calibration Matters

Speed matters in pharmaceutical packaging, but not at the cost of control. If the transfer conveyor runs too fast or unevenly, it can lead to product tipping, spacing issues, or jams. Setting the right pace also supports accurate inspection and counting later in the line.

Speed calibration facilitates:

● Consistent product spacing.

● Better label application.

● Fewer interruptions from jams or misfeeds.

Best Practices for Cleanroom Setup

Cleanrooms demand equipment that is easy to wipe down, non-porous, and resistant to chemical cleaners. A reliable side belt transfer conveyor designed with cleanroom standards helps maintain product safety and compliance.

In these areas, transfer lines should:

● Be free of unnecessary crevices

● Use non-absorbent belts

● Offer easy access for inspection and cleaning

Supporting Batch Sorting with an Accumulation Conveyor

As batches move through the packaging line, a well-designed accumulation conveyor can hold, group, or separate products before the final inspection or packing. This helps maintain order without stopping the line.

At CONOVEY, we build equipment for the pharmaceutical sector with product care and compliance in mind. Whether you need a precision-built transfer conveyor, transfer conveyor parts, or a controlled side belt transfer conveyor, every solution is built for real-world pharmaceutical applications.

Are you looking to add an accumulation conveyor or improve product transfer in your packaging line? Connect with CONOVEY to explore tailored options!