A submersible pump is an essential component for various applications, including domestic water supply, agricultural irrigation, and industrial use. However, the efficiency and safety of these pumps depend significantly on their control systems. One such crucial component is the automatic starter for submersible pump, which ensures smooth operation while protecting the pump from electrical faults and overloads.

With increasing demand for energy-efficient and safe water pumping solutions, automatic starters have gained popularity due to their advanced features and ease of use. In this guide, we will explore the significance of an automatic starter, its benefits, its working mechanism, its installation process, and the role it plays in improving pump efficiency and safety. Additionally, we will discuss the automatic pump controller price and the factors influencing its cost.

Understanding an Automatic Starter for Submersible Pump

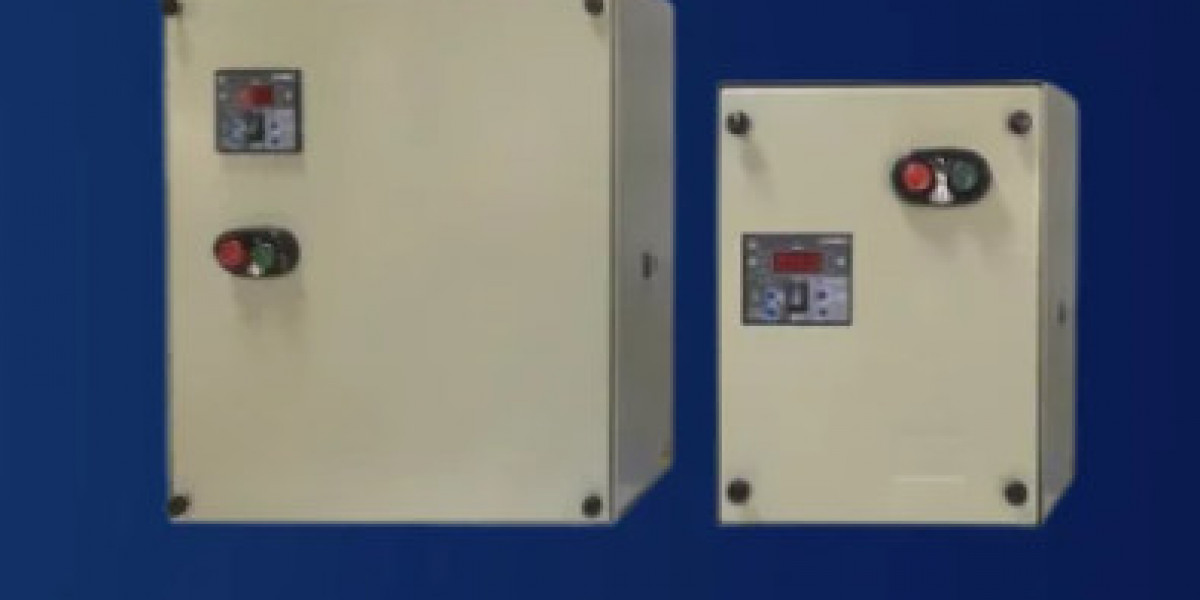

An automatic starter for submersible pump is an advanced control device designed to automate the starting and stopping of a submersible pump based on predefined conditions. It ensures optimal pump performance while safeguarding it from voltage fluctuations, phase failure, and overloading.

Key Components of an Automatic Starter

Contactor – Acts as a switch to control the power supply to the pump motor.

Overload Relay – Protects the pump from overheating due to excess current.

Voltage Sensing Circuit – Monitors input voltage and ensures stable operation.

Float Switch or Pressure Sensor – Detects water levels and automatically turns the pump on or off.

Control Panel – Displays operational status, errors, and manual override options.

Types of Automatic Starters

Direct-On-Line (DOL) Starter – Used for small motors, providing direct power supply with overload protection.

Star-Delta Starter – Suitable for high-power motors, reducing inrush current during startup.

Soft Starter – Limits voltage and current surges to ensure smooth motor operation.

Variable Frequency Drive (VFD) – Controls motor speed, optimizing energy consumption.

How an Automatic Starter Enhances Efficiency

Optimized Power Consumption

An automatic starter for submersible pump helps regulate power usage by running the pump only when necessary.

Features like pressure sensors and float switches prevent unnecessary operation, reducing energy wastage and lowering electricity bills.

Smooth Pump Operation

Traditional manual starters can lead to sudden voltage fluctuations when the pump starts, affecting the motor lifespan.

An automatic starter gradually supplies power, ensuring a smooth transition and minimizing mechanical stress.

Prevents Dry Running

Dry running occurs when the pump operates without water, causing severe damage. Automatic starters prevent this by using sensors that detect water levels and shut down the pump if necessary.

Protection Against Voltage Fluctuations

Voltage instability can damage the pump motor. An automatic starter continuously monitors voltage levels and disconnects the power supply if fluctuations exceed safe limits.

Efficient Water Management

For applications like irrigation and domestic water supply, maintaining the right water pressure is crucial. Automatic starters regulate pump operation based on water demand, preventing unnecessary cycles and maintaining consistent pressure.

How an Automatic Starter Enhances Safety

Overload and Short Circuit Protection

Excessive current draw can overheat the motor and cause short circuits. Automatic starters come with overload relays that cut off power in case of excess current, preventing fire hazards and motor damage.

Phase Failure Detection

For three-phase submersible pumps, a missing phase can cause imbalance, leading to severe damage. An automatic starter detects phase failure and stops the pump before any harm occurs.

Remote Monitoring and Control

Modern automatic starters allow remote monitoring and control via mobile apps or IoT-enabled systems. This ensures real-time status updates and immediate fault detection, enhancing overall safety.

Prevents Manual Errors

Manual operation increases the risk of operator errors, leading to motor burnout or inefficient performance. Automatic starters eliminate human intervention, ensuring proper start-stop sequences.

Water Level Monitoring

Automatic starters integrated with float switches or pressure sensors ensure that the pump operates only when required, preventing tank overflow or dry running.

Installation and Setup of an Automatic Starter

Step 1: Selecting the Right Automatic Starter

When choosing an automatic starter for submersible pump, consider factors like motor power rating, voltage compatibility, and protection features.

Step 2: Wiring the Starter to the Pump

Connect the power supply to the starter.

Wire the motor terminals to the contactor.

Integrate sensors such as float switches or pressure controllers.

Ensure proper earthing to prevent electrical hazards.

Step 3: Configuration and Testing

Set overload protection parameters based on motor specifications.

Test start and stop operations to ensure correct functionality.

Check safety features such as dry-run protection and voltage monitoring.

Automatic Pump Controller Price: Factors Influencing Cost

The automatic pump controller price varies based on several factors, including:

Type of Starter – DOL starters are cheaper, while VFD-based controllers are expensive.

Brand and Quality – High-end brands offer better durability and features, affecting price.

Control Features – Advanced features like remote monitoring and IoT integration increase costs.

Motor Capacity – Starters for high-power motors are more expensive than those for small pumps.

Installation Complexity – Some models require professional installation, adding to the overall cost.

Price Range of Automatic Pump Controllers

Basic DOL starters: $50 - $150

Star-Delta starters: $100 - $300

Soft starters: $200 - $500

VFD-based controllers: $500 - $1500

Choosing the Best Automatic Starter for Your Submersible Pump

When selecting an automatic starter for submersible pump, consider the following:

Power Rating – Ensure compatibility with your pump’s voltage and power requirements.

Protection Features – Look for overload, phase failure, and voltage fluctuation protection.

Automation Level – Choose a model with water level sensors for optimal efficiency.

Brand Reputation – Opt for a trusted manufacturer for quality assurance.

Budget Considerations – Balance between features and cost to get the best value.

Conclusion

An automatic starter for submersible pump is a vital component for ensuring efficiency and safety in water pumping systems. It helps regulate power consumption, prevents damage from voltage fluctuations, and automate pump operation for hassle-free performance. Additionally, investing in a high-quality starter can extend the lifespan of your pump while reducing maintenance costs.

When considering an automatic starter, it is important to factor in the automatic pump controller price and choose a model that best suits your needs. Whether for residential, agricultural, or industrial applications, having a reliable automatic starter enhances operational efficiency and safeguards your investment.

For high-quality electrical and automation solutions, including advanced pump control systems, Lauritz Knudsen Electrical & Automation offers top-tier products tailored for various applications. Investing in the right starter not only improves pump performance but also ensures long-term reliability and safety.