Introduction to UV DTF Transfers

UV DTF (Direct-to-Film) transfers are gaining popularity in the custom printing industry due to their versatility, durability, and high-quality output. This innovative printing technology offers a unique way to apply vibrant and detailed designs to various surfaces, including textiles, plastics, glass, wood, and metal. In this guide, we’ll explore what UV DTF transfers are, how they work, their advantages, and why they are a game-changer for businesses and individuals alike.

What Are UV DTF Transfers?

UV DTF transfers are a type of printing technology that uses ultraviolet (UV) light to cure ink on a transfer film. Once printed and cured, the design can be applied to a substrate with strong adhesive properties, making it a durable and long-lasting solution for custom designs. Unlike traditional printing methods, UV DTF does not require heat pressing or special coatings, allowing for a seamless transfer process.

How Do UV DTF Transfers Work?

The process of UV DTF transfers involves the following key steps:

Design Preparation: The design is created using graphic design software and formatted for UV printing.

Printing: A UV printer prints the design onto a specialized transfer film using UV-cured ink.

Curing: UV light instantly cures the ink, making it ready for transfer.

Application: The printed and cured design is then transferred onto the desired surface using an adhesive backing.

Peeling: After pressing the design onto the surface, the film is peeled away, leaving a vibrant and high-quality print.

Benefits of UV DTF Transfers

UV DTF transfers offer several advantages over traditional printing methods, making them an ideal choice for businesses and DIY enthusiasts alike.

1. High-Quality Prints

UV DTF transfers produce vibrant colors, sharp details, and a glossy finish, ensuring professional-quality results.

2. Durability

The cured ink forms a strong bond with the substrate, making UV DTF prints resistant to water, scratches, and fading over time.

3. Versatility

Unlike other printing methods, UV DTF transfers can be applied to various materials, including:

Fabric

Plastic

Wood

Metal

Glass

4. No Heat Press Required

Unlike traditional heat transfer methods, UV DTF does not require a heat press, making it a more accessible and convenient option for small businesses and hobbyists.

5. Cost-Effective

With UV DTF transfers, there is no need for expensive pre-treatments or special coatings, making the process more affordable in the long run.

Applications of UV DTF Transfers

UV DTF transfers are widely used across various industries due to their versatility. Some popular applications include:

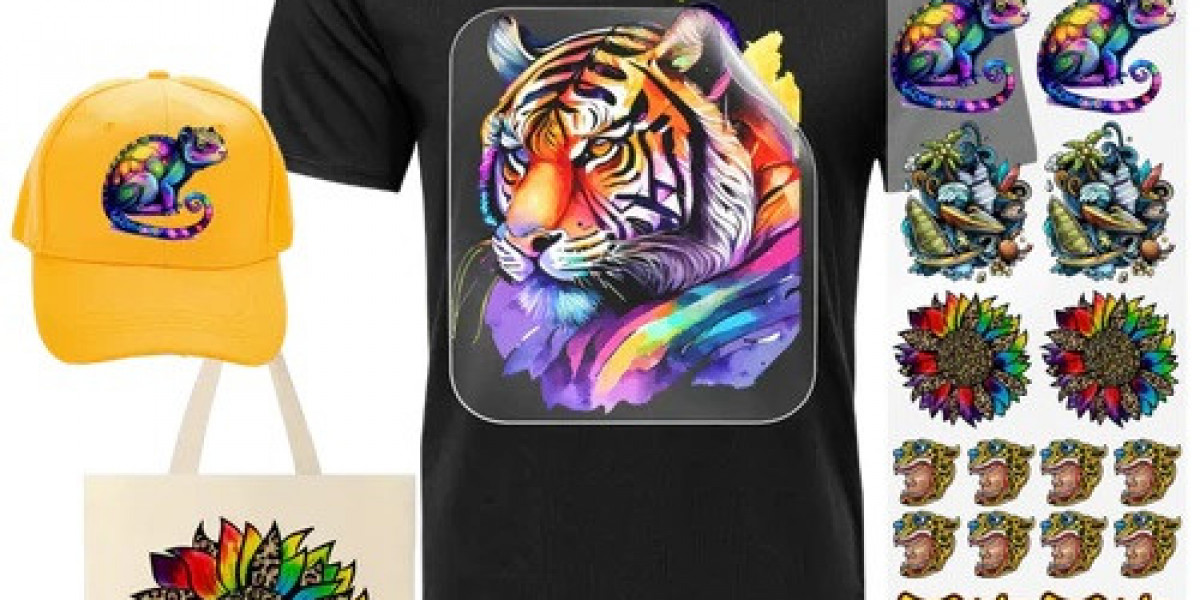

1. Custom Apparel and Accessories

T-shirts, hats, bags, and other fashion accessories can be easily customized with UV DTF transfers.

2. Personalized Gifts

From mugs to phone cases, UV DTF transfers allow for unique and personalized gifts that stand out.

3. Signage and Branding

Businesses use UV DTF transfers for branding and promotional materials, including stickers, decals, and signage.

4. Home Decor

Customizing home decor items such as glassware, picture frames, and furniture becomes effortless with UV DTF printing.

How to Use UV DTF Transfers Effectively

To achieve the best results with UV DTF transfers, follow these tips:

Choose the Right Film: Use high-quality transfer film to ensure a smooth and effective application.

Prepare the Surface: Ensure the surface is clean and dry before applying the transfer to achieve better adhesion.

Apply Even Pressure: Press the transfer evenly to avoid air bubbles and wrinkles.

Peel Carefully: Gently peel off the film after application to avoid smudging or misalignment.

UV DTF vs. Other Printing Methods

UV DTF vs. Sublimation Printing

UV DTF can be applied to various surfaces, while sublimation is mainly for polyester fabrics.

Sublimation requires heat and pressure, whereas UV DTF does not.

UV DTF vs. Screen Printing

Screen printing is labor-intensive and requires multiple steps, whereas UV DTF is straightforward and quick.

UV DTF offers finer details and vibrant colors compared to traditional screen printing.

Is UV DTF Transfer Right for You?

If you’re looking for a high-quality, durable, and cost-effective printing solution, UV DTF transfers are an excellent choice. Whether you are a business owner, an artist, or a DIY enthusiast, this technology allows you to create stunning custom prints with minimal effort.

Conclusion

UV DTF transfers are revolutionizing the custom printing industry by offering a versatile, high-quality, and user-friendly solution. With the ability to print on various surfaces without heat pressing, this method is becoming a favorite among small businesses, crafters, and printing professionals. As technology advances, UV DTF is set to become an even more popular choice for creative and commercial applications.

By understanding how UV DTF transfers work and their numerous benefits, you can take advantage of this cutting-edge printing technology to create stunning, durable, and professional-quality designs.