Introduction

In the ever-evolving world of custom printing, https://www.picassoprintdtf.com/pages/ready-to-press-dtf-transfers have gained immense popularity due to their ease of use, durability, and high-quality results. Whether you are a business owner, hobbyist, or professional printer, DTF (Direct to Film) transfers offer a game-changing solution for creating vibrant, long-lasting designs on various fabrics.

This article explores everything you need to know about DTF transfers, including their benefits, application process, and how they compare to other printing methods.

What Are DTF Transfers Ready to Press?

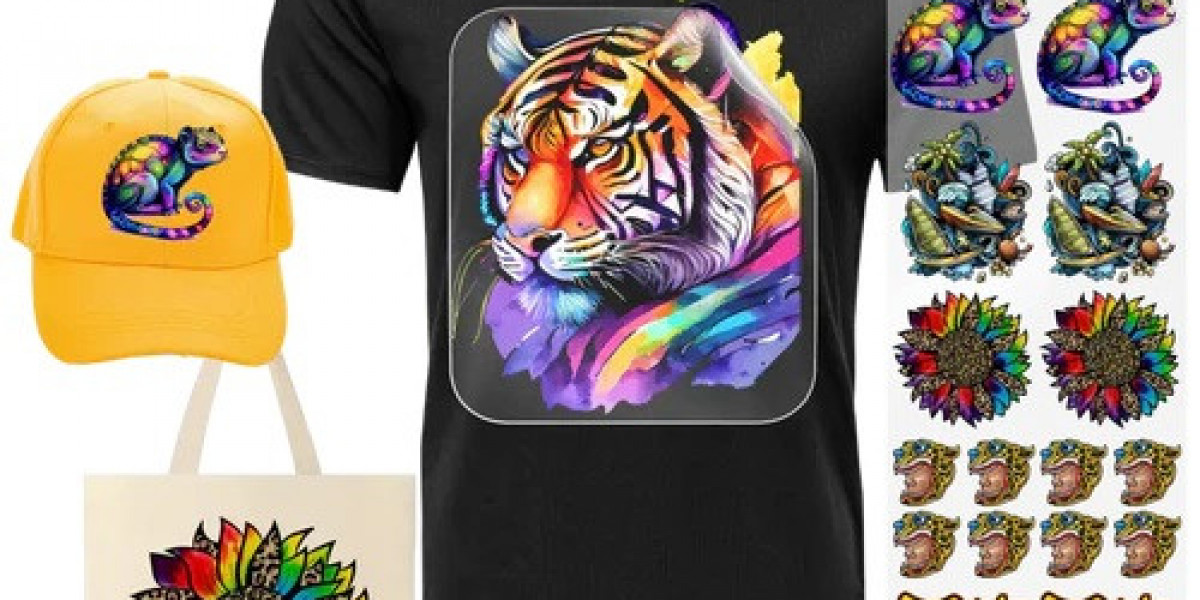

DTF (Direct to Film) transfers ready to press are pre-printed designs that can be directly applied to garments using a heat press. These transfers eliminate the need for complex screen printing setups, making them a convenient option for beginners and professionals alike.

Unlike traditional methods, DTF transfers work on a variety of materials, including cotton, polyester, blends, leather, and more. Their versatility and ease of application have made them a preferred choice in the custom printing industry.

Benefits of Using DTF Transfers Ready to Press

1. High-Quality Prints

DTF transfers produce sharp, vibrant, and high-resolution prints that last through multiple washes without fading or cracking. The colors remain bright and crisp, making them perfect for detailed designs.

2. Versatility

Unlike other printing methods that work only on specific fabrics, DTF transfers can be applied to various materials, including dark and light-colored garments.

3. Ease of Use

With DTF transfers, there’s no need for expensive equipment or extensive training. Simply place the transfer on the fabric, apply heat and pressure, and peel away the film for a flawless design.

4. Durability

DTF transfers are known for their durability. They withstand frequent washing and wear without peeling or cracking, making them a reliable choice for custom apparel businesses.

5. Cost-Effective

Compared to screen printing and DTG (Direct to Garment) printing, DTF transfers require minimal investment in equipment, making them an affordable option for small businesses and individuals.

How to Apply DTF Transfers Ready to Press

Applying DTF transfers is a straightforward process. Follow these simple steps to achieve professional-quality results:

Step 1: Prepare Your Fabric

Ensure the fabric is clean and free of dust, lint, or wrinkles. Pre-pressing the garment for a few seconds removes moisture and smooths out the surface.

Step 2: Position the Transfer

Place the DTF transfer on the fabric with the design facing upward. Use heat-resistant tape if necessary to keep it in place.

Step 3: Apply Heat and Pressure

Using a heat press, set the temperature between 300-325°F (149-163°C) and apply medium to firm pressure for 10-15 seconds.

Step 4: Peel the Film

Once pressed, let the transfer cool for a few seconds before peeling the film. Depending on the type of transfer, you may need to do a warm peel or cold peel.

Step 5: Final Press (Optional)

For added durability, perform a final press by covering the design with a parchment sheet or Teflon sheet and applying heat for another 5-10 seconds.

DTF Transfers vs. Other Printing Methods

DTF vs. Screen Printing

Cost: DTF transfers require minimal setup costs, whereas screen printing involves expensive equipment and chemicals.

Fabric Compatibility: DTF works on multiple fabrics, while screen printing is limited to certain materials.

Complexity: DTF is beginner-friendly, whereas screen printing requires skill and experience.

DTF vs. Direct-to-Garment (DTG) Printing

Color Vibrancy: DTF transfers often produce more vibrant colors compared to DTG printing.

Durability: DTF prints last longer without fading or cracking.

Fabric Type: DTG works best on cotton, whereas DTF transfers work on a variety of fabrics.

DTF vs. Vinyl Heat Transfer

Detail & Texture: DTF allows for intricate designs, while vinyl heat transfer is limited to simpler shapes.

Flexibility: DTF transfers offer a softer feel on fabric, while vinyl can be thicker and less flexible.

Where to Buy High-Quality DTF Transfers Ready to Press

If you’re looking for premium-quality DTF transfers, there are several online and offline suppliers specializing in pre-made and custom designs. Some of the top options include:

Etsy – Great for custom and pre-designed transfers

Amazon – Offers bulk purchasing options

Local Print Shops – Some printing businesses offer DTF transfer services

Specialty Websites – Companies specializing in DTF printing provide high-quality options

When purchasing, ensure the transfers are printed with high-quality ink and PET film for the best results.

Tips for Storing and Handling DTF Transfers

To maintain the quality of your DTF transfers ready to press, follow these storage and handling tips:

Keep in a Cool, Dry Place – Avoid exposure to humidity and direct sunlight.

Store Flat – Prevent bending or curling by storing transfers flat.

Use within Recommended Time – Most transfers have a shelf life, so check the manufacturer’s guidelines.

Conclusion

DTF transfers ready to press have transformed the custom printing industry by offering a simple, versatile, and cost-effective solution for creating high-quality apparel. Whether you’re a business owner looking to expand your product offerings or a DIY enthusiast exploring custom designs, DTF transfers provide a reliable and durable printing option.

With their ease of application, superior durability, and vibrant colors, DTF transfers ready to press are the perfect choice for anyone looking to create professional-grade printed garments with minimal effort.

FAQs

1. Can I wash garments with DTF transfers?

Yes! DTF transfers are highly durable and can withstand multiple washes without fading or peeling. For best results, wash garments inside out in cold water and avoid harsh detergents.

2. Do I need a special printer for DTF transfers?

If you are creating DTF transfers from scratch, you’ll need a DTF printer. However, if you purchase ready-to-press transfers, you only need a heat press.

3. Can I use a household iron instead of a heat press?

While a heat press is recommended for the best results, you can use a household iron with firm pressure and consistent heat. However, results may not be as durable.

4. Are DTF transfers better than sublimation?

DTF transfers work on various fabrics and colors, while sublimation is limited to polyester and light-colored garments. If you need versatility, DTF is a better choice.

5. How long do DTF transfers last?

With proper care, DTF transfers can last as long as screen-printed designs, typically around 50+ washes without significant fading.

By incorporating DTF transfers ready to press into your printing business or DIY projects, you can enjoy a hassle-free, high-quality printing method that meets various needs. Get started today and explore the endless possibilities of DTF technology!