Excavators are indispensable machines on construction sites, mining operations, and agricultural fields. While their hydraulic systems, engines, and undercarriages often take center stage, one crucial yet often overlooked component is the AC cabin filter. The excavator AC cabin filter plays a vital role in maintaining air quality inside the operator’s cabin, contributing to both human health and machine efficiency.

As modern excavators are expected to perform in increasingly demanding and dusty environments, the cabin’s air filtration system becomes more critical than ever. In this article, we’ll explore what AC cabin filters do, why they matter, and how to choose and maintain the right filter for your equipment.

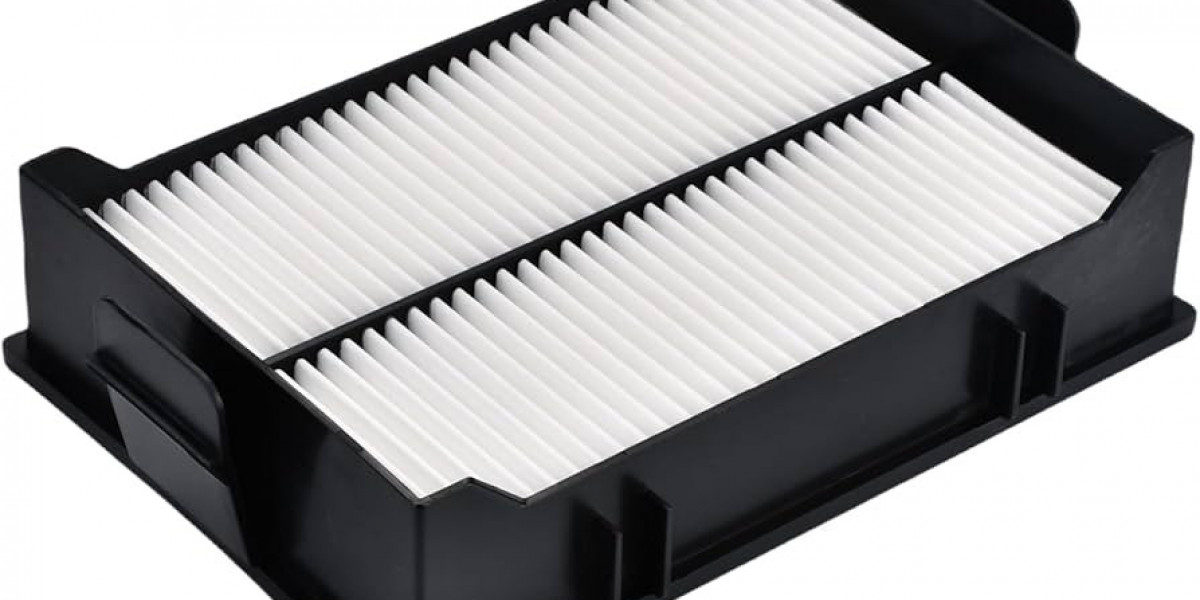

What Is an Excavator AC Cabin Filter?

An AC (air conditioning) cabin filter in an excavator is a filter element installed in the HVAC (heating, ventilation, and air conditioning) system of the operator cabin. Its primary function is to trap dust, dirt, pollen, allergens, and even airborne pathogens before they enter the cabin.

Unlike standard engine or hydraulic filters that protect machinery components, AC cabin filters are designed to protect the operator’s respiratory health and ensure clear visibility by preventing the buildup of dust on the interior surfaces.

Why Are AC Cabin Filters Essential in Excavators?

1. Protecting Operator Health

Job sites are notorious for high dust levels, chemical exposure, and airborne particulates from demolition, excavation, or material handling. Prolonged exposure to these can cause:

Respiratory issues such as asthma, bronchitis, or chronic cough

Allergic reactions to pollen or mold spores

Fatigue and discomfort, reducing productivity

A clean, high-quality cabin filter ensures a constant flow of fresh, filtered air, reducing health risks and improving operator comfort.

2. Reducing Equipment Downtime

Clogged or ineffective cabin filters can cause HVAC systems to overwork or malfunction. Without proper air circulation, air conditioning performance drops, and visibility may decrease due to condensation and dust buildup inside the glass.

This leads to:

Reduced operator efficiency

More frequent maintenance calls

Potential HVAC system failures

A well-functioning filter reduces wear and tear on the HVAC system, extending its service life and ensuring fewer unexpected repairs.

3. Maintaining Regulatory Compliance

In many regions, especially within mining and industrial sectors, maintaining a safe working environment includes ensuring air quality within machinery cabs. Poor filtration may violate occupational safety guidelines, leading to penalties or work stoppages.

Using proper filters helps meet health and safety standards such as those from OSHA, MSHA, or local environmental agencies.

Types of Excavator AC Cabin Filters

There are several kinds of cabin filters used in excavators, each suited to different environments and machine models:

Standard Particulate Filters

These filters are designed to trap dust, dirt, and large airborne particles. They are suitable for general-purpose applications and provide baseline protection in moderate environments.

Activated Carbon Filters

These filters include a layer of activated charcoal that absorbs odors, fumes, and harmful gases such as diesel exhaust and volatile organic compounds (VOCs). They are ideal for urban or industrial job sites.

HEPA Filters (High-Efficiency Particulate Air)

HEPA filters provide the highest level of filtration, capturing up to 99.97% of airborne particles, including fine dust, allergens, and pathogens. These are typically used in high-dust environments like quarries or areas with hazardous materials.

Signs Your Cabin Filter Needs Replacement

An AC cabin filter isn’t a “set and forget” component. Like any filter, it becomes less effective over time. Common signs of a dirty or failing cabin filter include:

Reduced airflow from AC vents

Dust or odor buildup in the cabin

Foggy windows or poor defogging

Increased HVAC noise

Operator complaints of allergies or discomfort

Ignoring these signs can lead to long-term health problems and HVAC system failure.

Recommended Maintenance Intervals

While maintenance schedules vary by manufacturer and working conditions, a general rule of thumb is to:

Inspect cabin filters every 250 hours

Replace every 500 hours (or more frequently in extreme conditions)

Operators working in dusty or polluted environments such as mining, demolition, or agriculture should consider checking filters more often.

How to Choose the Right Excavator Cabin Filter

Choosing the right filter depends on several factors:

1. Machine Make and Model

Filters are typically designed for specific excavator models. Always check the OEM part number or consult your parts supplier for compatibility.

2. Environmental Conditions

Assess the typical job site conditions. For high dust, go for HEPA or dual-layer filters. For urban or chemical exposure, choose activated carbon types.

3. Budget vs. Protection

While premium filters cost more upfront, they often last longer and provide superior protection. Weigh the cost against potential downtime or health issues.

4. Supplier Reliability

Choose trusted suppliers that offer OEM-quality filters. For example, CT Parts is known for providing durable and performance-tested AC cabin filters compatible with a wide range of excavator brands like Caterpillar, Komatsu, Hitachi, and more.

Installation Tips and Best Practices

Proper installation is essential for filter performance. Here are some key tips:

Turn off HVAC and engine before starting

Access the filter housing, usually behind the glove box or under a panel

Remove debris and vacuum the area

Insert the new filter in the correct orientation (check airflow arrows)

Secure housing cover tightly to prevent leaks

Always refer to your excavator’s service manual for specific instructions.

Benefits of Maintaining Your Cabin Filter

Regular cabin filter maintenance delivers several tangible benefits:

| Benefit | Description |

|---|---|

| Improved air quality | Keeps operators healthy and alert |

| Extended HVAC life | Reduces strain on the system |

| Reduced cabin cleaning | Less dust accumulation inside |

| Lower energy consumption | Optimizes AC system efficiency |

| Compliance with safety standards | Meets workplace health regulations |

Conclusion

The excavator AC cabin filter may seem like a minor component compared to the engine or hydraulic system, but its role is far from insignificant. It serves as a critical defense mechanism shielding operators from harmful airborne particles, preserving HVAC performance, and ensuring compliance with safety standards.

For machine owners and fleet managers, prioritizing cabin filter maintenance is a smart investment in both operator well-being and equipment longevity. By using high-quality filters from reputable suppliers like CT Parts, you can significantly reduce downtime, increase comfort, and maximize overall productivity on the job site.

So next time you’re performing maintenance on your excavator, don’t overlook the AC cabin filter it’s a small part that delivers big protection.