The extruded polystyrene market is seeing increased demand as industries like construction, packaging, and automotive continue to expand. Known for its excellent insulation properties, moisture resistance, and high compressive strength, extruded polystyrene is widely used in applications requiring thermal insulation. However, this market faces several challenges, even as it provides multiple growth opportunities.

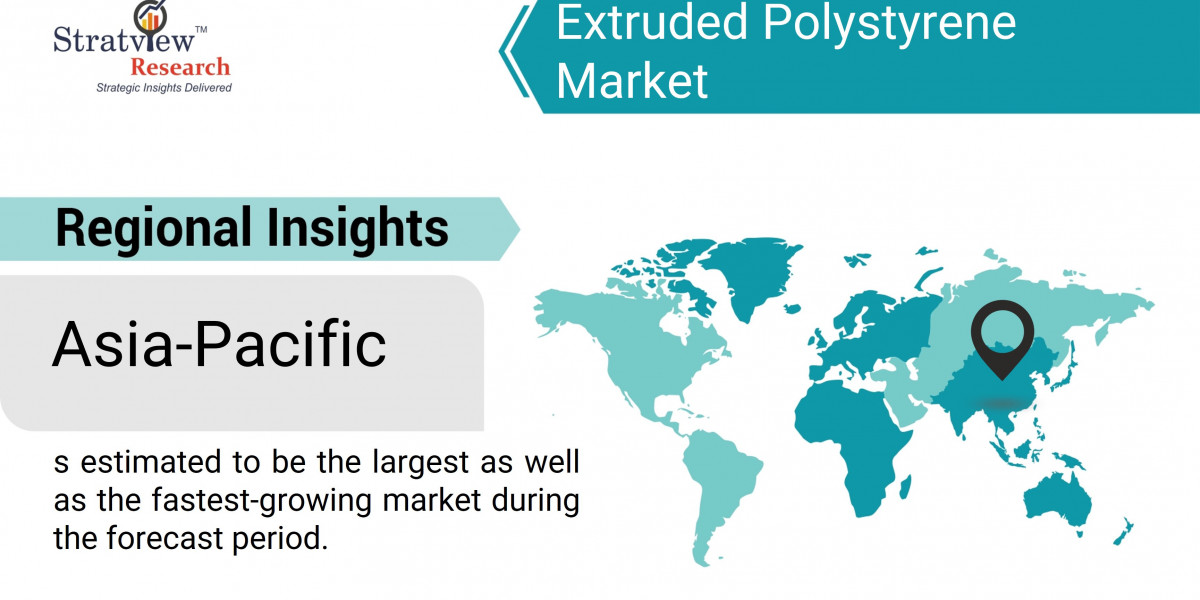

According to Stratview Research, the extruded polystyrene market was estimated at USD 6.15 billion in 2022 and is likely to grow at a CAGR of 3.97% during 2023-2028 to reach USD 7.79 billion in 2028.

Key Challenges

- Environmental Concerns and Regulations: As industries move toward sustainable practices, extruded polystyrene faces scrutiny due to its environmental impact. Traditional manufacturing processes for extruded polystyrene involve the use of harmful hydrofluorocarbons (HFCs) as blowing agents, which contribute to greenhouse gas emissions. In response, regulatory bodies, especially in North America and Europe, have imposed stricter environmental standards, pushing companies to innovate or risk non-compliance. Shifting to eco-friendly blowing agents is costly, posing a challenge for manufacturers in transitioning toward more sustainable production.

- Rising Raw Material Costs: The cost of raw materials, particularly polystyrene and chemicals used in production, has been volatile. Supply chain disruptions and fluctuations in crude oil prices impact these costs, as polystyrene is a petroleum-derived product. High raw material costs directly affect the profit margins of extruded polystyrene manufacturers, presenting a financial challenge, especially for smaller companies.

- Increasing Competition from Substitute Products: Alternative insulation materials like expanded polystyrene (EPS), polyurethane foam, and mineral wool are popular due to their competitive pricing and varying properties. EPS, in particular, is less dense and often less expensive than extruded polystyrene, making it a viable substitute in several applications. The presence of these alternatives requires extruded polystyrene manufacturers to continuously differentiate their products based on quality and performance.

Key Opportunities

- Growing Demand in the Construction Industry: With increased urbanization and infrastructure development worldwide, demand for insulation materials in the construction sector is growing. Extruded polystyrene offers high thermal efficiency and moisture resistance, making it ideal for use in commercial and residential buildings. As energy efficiency becomes a priority, there is a notable increase in demand for extruded polystyrene in green building projects, particularly in emerging economies.

- Technological Advancements in Manufacturing: Innovation in eco-friendly blowing agents and manufacturing processes presents a significant growth opportunity. By developing extruded polystyrene products that meet environmental regulations without compromising performance, companies can tap into the expanding market of sustainable construction materials. Additionally, innovations such as the use of recycled polystyrene in production can reduce costs and appeal to environmentally conscious consumers.

- Expansion in Emerging Markets: Rapid urbanization and economic growth in regions like Asia-Pacific and Latin America are creating demand for high-quality insulation materials. The construction of energy-efficient buildings is gaining importance, offering an opportunity for extruded polystyrene manufacturers to expand in these regions.

Conclusion

While the extruded polystyrene market faces challenges from regulatory pressures and raw material costs, opportunities in green construction, innovation, and emerging markets provide pathways for growth. Companies that adapt to sustainability trends and invest in eco-friendly solutions are well-positioned to thrive in the evolving market landscape.